An environmental testing chamber, sometimes referred to as a humidity chamber, climatic compartment, stability test room, or just test chamber, is used to investigate how different climatic, physical, and other unusual variables affect a product. They are intended to create conditions that a product might experience while being used. In order to test and evaluate a product’s qualities, research depends on them to create controlled environments that can be altered, such as moisture, temperature variations, and low or high pressure. The impacts of a product or material are tested in an environmental chamber under predetermined environmental conditions in a variety of sectors. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Hastest Solutions designs, manufactures and provides solutions for all environmental testing needs. For the full range of environmental test chambers, including HAST, temp/humidity, salt fog, solar radiation, high temp ovens, autoclave, and more.

Since 1959, Associated Environmental Systems (AES) has designed, manufactured, and serviced standard and custom environmental test chambers, as well as patented and patent-pending battery testing solutions. Built in the USA for precision and reliability, AES helps the world’s leading innovators test, validate, and deliver products that perform in the real world.

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Test Chamber Manufacturers

Environmental test chambers are used to evaluate a product's or material's performance under a range of conditions, such as heat, wetness, elevation, vibration, and light. By recreating the conditions under which an item or material will be used, manufacturers may assure that their goods will perform as anticipated in the actual world. The standard testing chambers are created specifically to produce the testing conditions. Additionally, chambers can be used to simulate environments that do not exist on Earth, like the vacuum of space.

Environmental Chamber Types

Environmental chambers come in many designs, each of which is intended to produce a particular set of testing conditions. The following are a few of the most typical types of chambers:

Altitude Chambers

Replicating the gaseous and pressure conditions seen at various elevations, altitude chambers are also known as hypobaric chambers. In altitude chambers, not only are items subjected to simulated high altitudes, but so are human test subjects who are anticipating exposure to changes in altitude and the lower oxygen levels that come along with such changes. This comprises aspiring pilots as well as divers, climbers, and sportsmen. Altitude chambers are crucial instruments in the aviation, aerospace, automobile, and military sectors because to the delicate nature of their technology and tasks.

Cryogenic Chambers

Test chambers that use liquid nitrogen to replicate situations with extremely low temperatures, typically between 0 °F (-18 °C) to -238 °F (-150 °C) or lower. The effects of abrupt temporal shifts as well as high temperatures are studied in temperature chambers, which include cryogenic chambers.

Thermal Shock Chambers

Thermal shock chambers measure how a product responds to rapid temperature fluctuations in terms of stress and strain. They specifically monitor thermal shock, as implied by their name. The conflict caused by uneven component expansion and compression induced during heating or cooling results in thermal shock, which leads to faulting or splitting along lines of stress. Glass and ceramics are particularly susceptible to thermal shock due to their limited heat conductivity and propensity to compress and expand unevenly. This is the rationale behind the widespread usage of thermal shock chambers in a variety of industries, such as construction, medical, aerospace, automotive, and consumer goods.

Pressure Chambers

Pressure chambers, which can endure both high and low pressure situations, are used to test products under various types of extreme pressure. To prevent explosions and malfunctions, the chamber's operation needs to be closely watched. They can replicate pressure at varying ocean depths as well as pressure at high elevations, both static and fluctuating. The chamber's atmospheric pressures can be increased to 60,000 psi or decreased to produce a vacuum.

Vacuum Chambers

In vacuum chambers, air and pressure are removed from an enclosed space so that the materials' reactions to a vacuum may be studied. Regulations for the defense and aerospace industries mandate that items be tested in a vacuum. Vacuum testing is a technique used by spacecraft engineers to examine the electronics, circuitry, optics, filters, and structural components of a spacecraft. Additionally, air bubbles in synthetic resin that will be injected into a mold are eliminated using vacuum chambers.

AGREE Chambers

The letters AGREE means "Advisory Group on Reliability of Electronic Equipment" in AGREE chambers. They have the name of the United States Defense Department team that first established their high requirements. AGREE chambers were first intended to test exclusively military hardware. However, they now offer a combination of vibration, humidity, and temperature testing to applications across a range of sectors. Even with heavy loads, they are capable of producing dramatic temperature fluctuations at rates of between 40 and 107 per minute. Their vibratory properties are based on the floor's detachable feature.

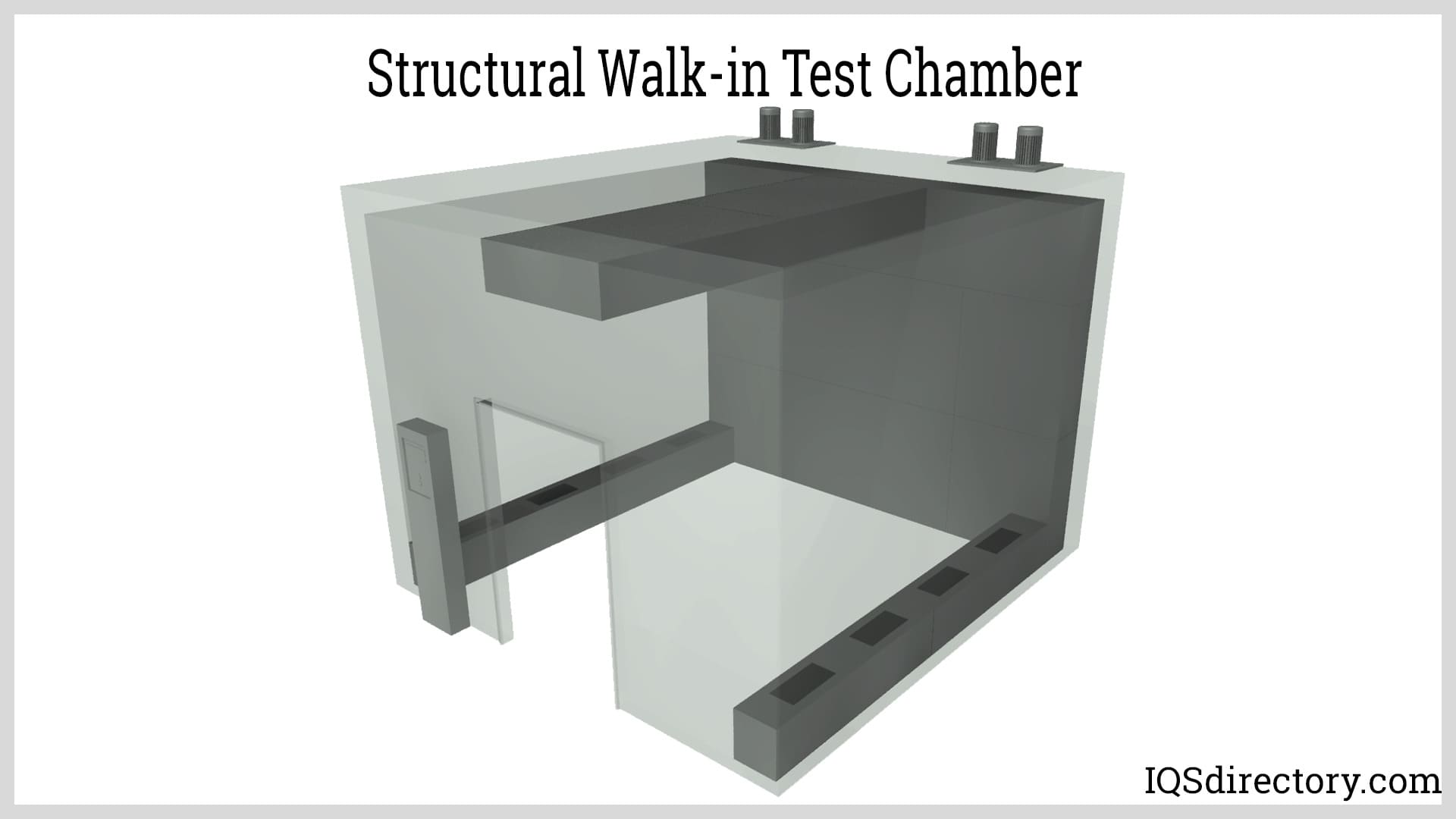

Walk-in Chambers

Large products can be tested and stored in walk-in test chambers. They range greatly in size, with some similar to a small closet and others as huge as a room. They are all big enough for a human to walk into. The tasks of other testing chambers, such as salt spray, thermal shock, and temperature testing, can all be carried out in walk-in chambers.

Choosing the Right Test Chamber Manufacturer

For the most beneficial outcome when purchasing a test chamber from a test chamber manufacturer, it is important to compare several companies using our directory of test chamber manufacturers. Each test chamber manufacturer has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the manufacturer for more information or request a quote. Review each test chamber business website to better understand what each company specializes in. Then, use our simple RFQ form to contact multiple test chamber companies with the same form.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services