Humidity chambers are used to examine how a product will react to varying humidity levels. This mechanism helps identify the safety level and expected shelf life of a product. The humidity chambers are designed to facilitate engineers and manufacturers by determining the length of the usefulness of the product. They also help in understanding the humidity level a product can withstand. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Our humidity chambers come in two standard configurations. Table top chambers have a humidity range of 30 to 95% RH while the medium size chambers have a humidity range of 20 to 98% RH. All of our chambers are equipped with powerful programmable controllers that include a LCD display. Our chambers are designed with “Go Green” features using an energy efficient method for heating and cooling....

Since 1959, Associated Environmental Systems (AES) has designed, manufactured, and serviced standard and custom environmental test chambers, as well as patented and patent-pending battery testing solutions. Built in the USA for precision and reliability, AES helps the world’s leading innovators test, validate, and deliver products that perform in the real world.

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Humidity Chamber Manufacturers

Humidity Chambers: Complete Guide, Applications, and Selection

Humidity chambers, also known as environmental chambers or climate test chambers, are advanced laboratory equipment designed for simulating and controlling environmental conditions, primarily humidity and temperature. These chambers are critical for quality assurance, product development, and reliability testing across various industries. By exposing materials, components, and finished products to precise levels of humidity and temperature, manufacturers can evaluate performance, safety, and durability under real-world or accelerated conditions.

If you're investigating humidity chamber features, comparing leading test chamber manufacturers, or seeking to understand how environmental simulation can improve product reliability, this comprehensive guide will address key questions and provide actionable insights.

What Is a Humidity Chamber and How Does It Work?

A humidity chamber is a controlled environment testing device engineered to simulate various levels of humidity and temperature. It is widely used as an extended testing chamber to record a product’s reaction to elevated moisture, temperature fluctuations, and prolonged exposure to harsh environmental conditions. By exposing samples for weeks or months, companies gain valuable data on product lifecycle, failure modes, and compliance with industry standards.

Depending on the application and required data, there are different varieties of humidity chambers that allow testing in both static and dynamic states. This versatility enables precise control over environmental parameters, ensuring repeatability and accuracy during accelerated aging studies, material degradation assessments, and component reliability evaluations.

Construction of Humidity Chambers

Humidity chambers are constructed with precision to guarantee accurate, repeatable, and reliable results. Their robust design ensures long-term durability, thermal stability, and resistance to corrosion or contamination. Key construction elements include:

- Double-walled construction: Chambers can be either welded or modular. Welded walls are preferred for their superior sealing, minimizing the risk of contamination and thermal leakage.

- Sealing materials: To prevent ingress of contaminants, advanced seals made from rubber, glass wool, silicone, or specialized polymers are used, ensuring an airtight environment.

- Temperature and humidity control: Integrated cooling compressors and heating coils maintain precise environmental conditions. PID controllers and advanced sensors provide real-time feedback and adjustment.

- Air circulation: Strategically placed air ducts, circulating wheels, or high-efficiency fans promote uniform temperature and humidity distribution throughout the chamber.

- Control systems: Programmable logic controllers (PLCs), touchscreen HMIs, and remote monitoring capabilities are often included for precise, user-friendly operation and data logging.

How Do Humidity Chambers Work?

Humidity chambers operate on the principle of controlling relative humidity and temperature to create a stable test environment. The relationship between temperature and humidity is critical; precise regulation of both factors is required for accurate simulation. The general working process involves:

- Maintaining a targeted dew point temperature, followed by reheating the chamber atmosphere to a specified air temperature.

- Stabilizing dew point levels to achieve constant relative humidity.

- Circulating air from the conditioned area through a controlled water spray zone, adjusting its temperature and humidity content.

- Cooling the air to water temperature, allowing it to reach saturation point and maximize moisture absorption.

- Removing excess water vapor via a mist eliminator, ensuring only the desired humidity level remains.

- Utilizing electric heaters to adjust air temperature as needed before recirculating it to the test area.

- Employing advanced sensors—such as RH (relative humidity) sensors—for automatic water spray temperature adjustment and real-time feedback.

- Achieving precise, stable, and repeatable humidity levels for reliable product testing and compliance with test protocols.

Want to learn more about how different chamber configurations impact humidity control or what sensors deliver the best accuracy? Explore our tips for choosing the best humidity chamber for your application.

Methods of Humidity Generation

Humidity generation is a critical design factor for environmental test chambers. Manufacturers use several methods to produce and regulate moisture within the chamber, each with unique advantages, maintenance requirements, and suitability for specific test scenarios. The most common methods include:

Steam Generators

- Steam generators produce humidity by heating water in specialized tanks equipped with immersion heaters.

- Integrated cooling coils and heaters on the chamber top facilitate rapid humidity adjustment.

- Heated water generates steam, which rises to the cooling coils, supplying desired relative humidity.

- Consistent vapor generation is ideal for large chamber volumes and demanding test protocols.

- Robust and reliable, steam generators support continuous, high-capacity humidity simulation.

Atomizer

- An atomizer uses a fine spray nozzle to atomize water, introducing micro-droplets into the air stream.

- Atomization occurs in a designated mixing assembly within the chamber.

- Upon entering the chamber, atomized water is instantly heated, rapidly increasing humidity levels.

- Atomizers are energy-efficient, simple to operate, and can generate large volumes of steam quickly.

- With fewer moving parts and no risk of heater burn-out, atomizers require less maintenance and offer long-term reliability.

Water Bath

- A water bath acts as an open-source steam generator located within the mixing assembly, alongside cooling coils and heaters.

- Incoming air picks up water vapor as it passes over the heated surface, achieving rapid humidity stabilization.

- Water baths are easy to clean, require less boiling (reducing mineral buildup), and are highly responsive due to minimal water volume.

- Suitable for applications where frequent chamber cycling and low-maintenance operation are priorities.

Types of Humidity Chambers

Humidity chambers are available in several configurations to accommodate a wide range of test requirements, sample sizes, and industry applications. Understanding the differences helps buyers select the best fit for their needs.

Bench-top Humidity Chamber

Bench-top chambers are compact, cost-effective, and ideal for testing small products, electronic components, or material samples. Designed for research labs, academic institutions, and small businesses, these units offer precise control and rapid cycling for short-term or specialized tests. Their small footprint makes them suitable for limited workspace environments.

Reach-in Humidity Chamber

Reach-in chambers offer a vertical, space-efficient configuration with easy-access doors and internal shelving. Available in multiple sizes, they are mounted on castors or wheels for mobility and flexibility. Suitable for medium-scale testing, these chambers are often used in electronics, pharmaceuticals, and plastics industries.

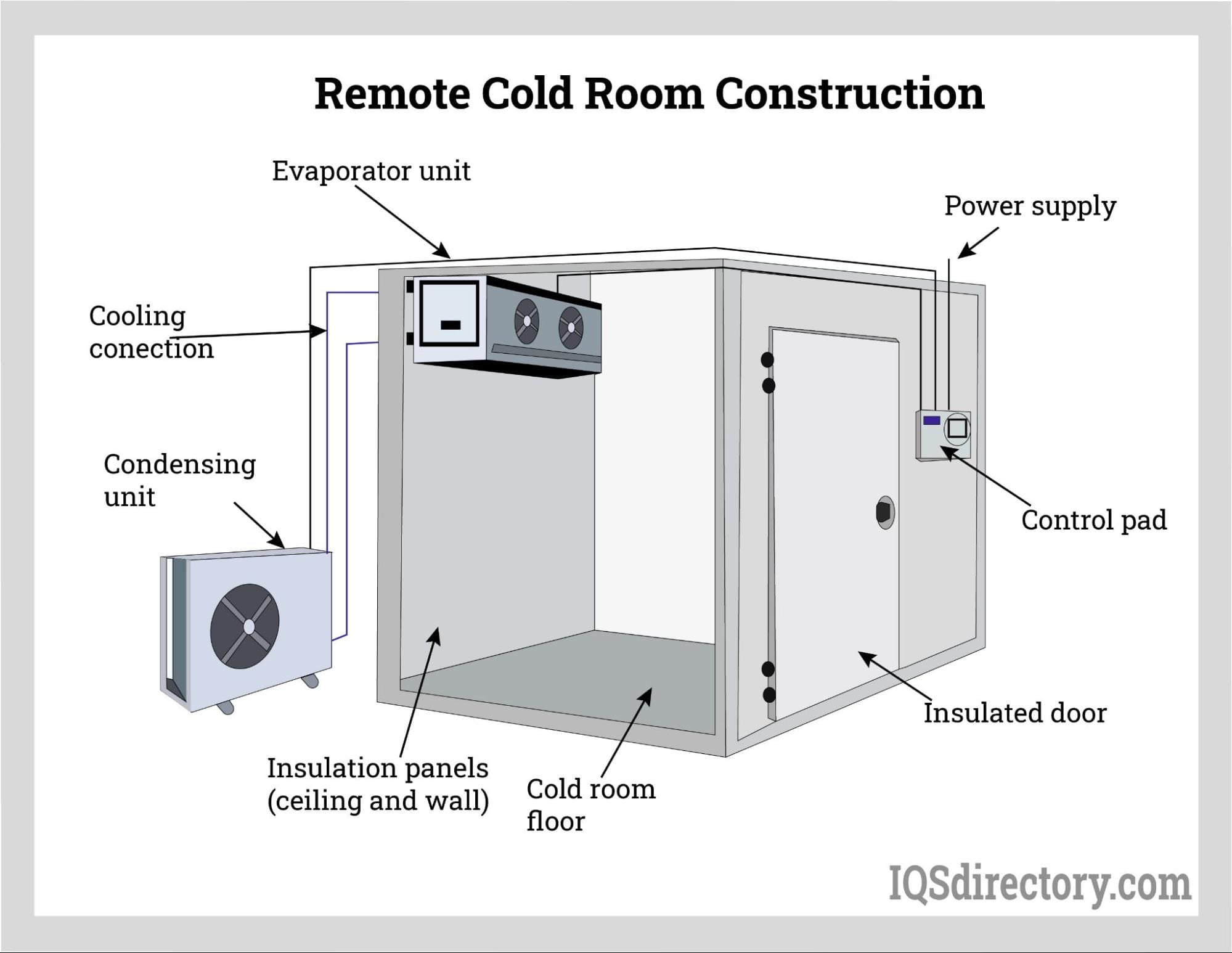

Walk-in Humidity Chamber

Walk-in humidity chambers feature modular construction and can be installed as a single unit or assembled on-site. With large internal volumes, they are essential for testing bulk materials, large assemblies, or multiple products simultaneously. Commonly used by automotive, aerospace, battery, and electronics manufacturers, walk-in chambers support long-duration, high-volume environmental simulation.

Drive-in Humidity Chamber

Drive-in chambers are the largest configuration, designed for full-scale vehicle or equipment testing. These chambers accommodate entire cars, trucks, or specialized machinery, enabling comprehensive evaluation of vehicle systems, interior materials, and critical components under controlled humidity and temperature cycles. They are indispensable for automotive R&D, military, and defense testing.

Key Benefits and Applications of Humidity Chambers

Humidity chambers provide a controlled environment for a wide variety of test scenarios, offering critical advantages for manufacturers, researchers, and quality control professionals. Their primary benefits include:

- Accelerated Life Testing: Simulate years of environmental exposure in weeks or months, identifying potential failure points before product launch.

- Material and Component Reliability: Evaluate how rubber, plastics, metals, coatings, and electronics withstand high humidity, condensation, and temperature cycles.

- Regulatory Compliance: Meet international standards (such as ASTM, MIL-STD, IEC, ISO) for product qualification, safety, and performance.

- Process Improvement: Refine manufacturing processes, adhesives, and assembly techniques based on real-world performance data.

- Research and Development: Enable scientists and engineers to develop new materials and components optimized for harsh or variable environments.

Typical Applications by Industry

- Pharmaceutical and Medical: Stability testing of drugs, packaging, and medical devices; ensuring efficacy and shelf-life.

- Automotive and Aerospace: Testing of electronic modules, sensors, interior trims, and structural components for corrosion, condensation, and electrical reliability.

- Electronics and Semiconductors: Assessing PCB assemblies, connectors, and encapsulations for moisture sensitivity and insulation resistance.

- Battery Manufacturing: Evaluating lithium-ion cells, battery packs, and energy storage systems for moisture ingress and performance under stress.

- Rubber and Plastics: Durability studies of seals, gaskets, hoses, and molded parts exposed to cyclic humidity and heat.

- Military and Defense: Environmental qualification of mission-critical systems, avionics, and weapon platforms.

How to Choose the Right Humidity Chamber for Your Needs

When selecting a humidity chamber, buyers should evaluate a range of factors to ensure optimal results, compliance, and long-term value. Consider the following decision criteria:

- Temperature and Humidity Range: What are the minimum and maximum values required for your test protocols? Are rapid ramp rates or extreme conditions needed?

- Chamber Size and Volume: What are the dimensions of the products or samples being tested? Does your application require a bench-top, reach-in, walk-in, or drive-in model?

- Uniformity and Stability: How consistent are the environmental conditions throughout the chamber? Look for models with advanced air circulation and calibration features.

- Control Systems and Data Logging: Do you need programmable test profiles, remote monitoring, or integration with laboratory information management systems (LIMS)?

- Compliance and Certification: Are there specific industry or regulatory standards your testing must meet (e.g., GLP, GMP, ISO 17025)?

- Maintenance and Serviceability: What are the ongoing maintenance requirements? Is technical support readily available from the manufacturer?

- Energy Efficiency and Operating Costs: Consider insulation quality, refrigeration efficiency, and water consumption—especially for high-throughput or 24/7 operations.

Ready to compare models or request a quote? Browse our directory of humidity chamber manufacturers and use our RFQ tool to connect with qualified suppliers.

Industries That Rely on Humidity Chambers

Humidity chambers are indispensable for a diverse array of industries, supporting rigorous product evaluation, regulatory compliance, and innovation. Key sectors include:

- Rubber and plastic manufacturing

- Pharmaceutical and biotechnology companies

- Automotive OEMs and suppliers

- Aerospace and aviation

- Military and defense contractors

- Electronics and semiconductor fabrication

- Medical device manufacturers

- Battery and energy storage developers

- Paints, coatings, and adhesives suppliers

Looking for case studies or industry-specific guidance? Contact leading humidity chamber manufacturers for custom recommendations.

Frequently Asked Humidity Chamber Questions

- What is the difference between a humidity chamber and a temperature chamber?

While both simulate environmental conditions, humidity chambers control both moisture and temperature, while temperature chambers focus primarily on thermal cycles. Many advanced models combine both functions for comprehensive testing. - How often should humidity chambers be calibrated?

Regular calibration—typically performed annually or as required by your quality system—is essential for maintaining accurate, traceable results. Most manufacturers offer calibration services. - Can I rent a humidity chamber instead of buying?

Yes, many suppliers offer humidity chamber rental or leasing options for short-term projects or pilot testing. This can reduce upfront costs and enable evaluation before purchase. - What safety features should I look for?

Essential safety features include over-temperature protection, door interlocks, water level monitoring, and automatic shutdown. Advanced models may include alarms, data backup, and remote diagnostics.

Choosing the Right Humidity Chamber Manufacturer

To ensure the best outcome when purchasing a humidity chamber, it's vital to compare multiple manufacturers and models. Use our comprehensive directory of humidity chamber manufacturers to research expertise, product lines, and customization capabilities. Each business profile provides in-depth information on experience, certifications, and unique technologies offered.

For streamlined sourcing, our proprietary website previewer enables you to quickly compare manufacturers’ capabilities. Once you’ve shortlisted suppliers, use our simple RFQ form to contact several companies simultaneously and request quotes, technical data, or application-specific advice.

Still have questions about which humidity chamber is best for your testing requirements? Connect with our experts today or explore our resource library for more in-depth guides and product comparisons.

Conclusion: Unlock the Benefits of Humidity Testing for Your Business

Humidity chambers play a pivotal role in product development, regulatory compliance, and quality assurance for countless industries. By understanding the different types, features, and applications of humidity test chambers, you can make informed decisions that enhance reliability, safety, and market success. Whether you need a compact bench-top unit for lab research or a drive-in system for automotive testing, selecting the right environmental test chamber ensures your products meet the highest standards under any conditions.

Ready to take the next step? Browse leading humidity chamber manufacturers, request quotes, and transform your product testing with advanced climate simulation solutions.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services