There are manufacturing processes that require a controlled environment where the temperature and amount of moisture in the air must be closely monitored. These types of environmental conditions are especially useful to manufacturers who produce products that are hygroscopic and moisture sensitive where variations in humidity and water vapors can significantly damage production. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Hastest Solutions designs, manufactures and provides solutions for all environmental testing needs. For the full range of environmental test chambers, including HAST, temp/humidity, salt fog, solar radiation, high temp ovens, autoclave, and more.

Since 1959, Associated Environmental Systems (AES) has designed, manufactured, and serviced standard and custom environmental test chambers, as well as patented and patent-pending battery testing solutions. Built in the USA for precision and reliability, AES helps the world’s leading innovators test, validate, and deliver products that perform in the real world.

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Dry Room Manufacturers

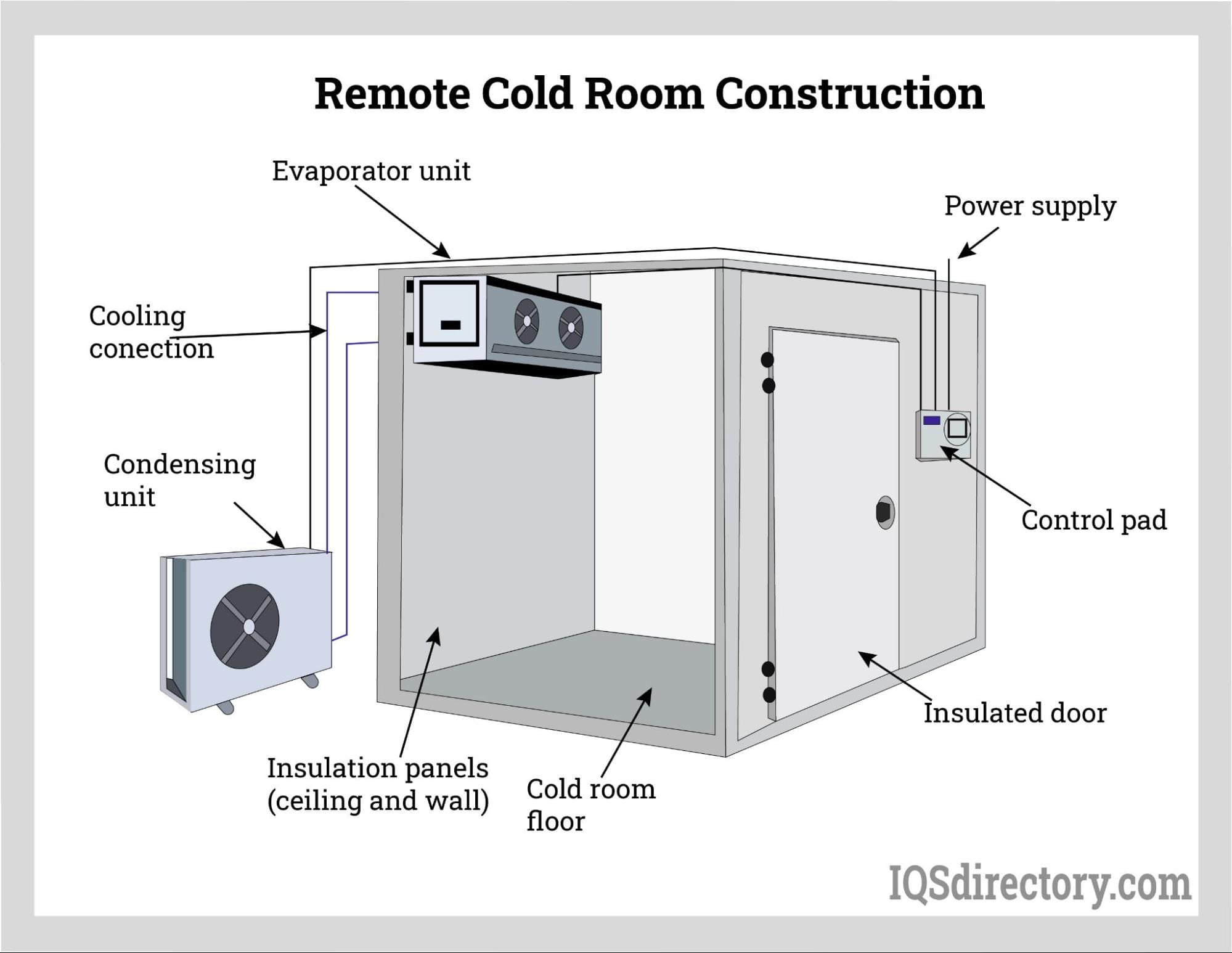

The control of moisture content in the air requires a room that is sealed to the extent that humidity is eliminated. The answer to how to create these conditions is found in dry rooms that can be easily fabricated and installed in any number of sizes. To guarantee the proper conditions for the room, a dehumidifier unit is used to remove water vapors and create the exacting conditions.

How a Dry Room is Constructed

The most important part of the development of a dry room is the design phase where each aspect of the rooms use is examined. The building of a special environment that is built to resist outside influences has to meet a certain set of standards to qualify as a dry room. Such a room has to be built to meet the requirements of the manufacturing process since the use of these special rooms varies depending on how they are used.

One of the major issues regarding the creation of a unique environment is the number of people who will use the room. Of all the possible factors that can contaminate specially designed rooms, people are the greatest problem since the human body carries many contaminants, viruses, and bacteria. In the design phase of a dry room, engineers develop restrictions for those who will be using the room and their coverings.

The most important determination in dry room design is deciding on the temperature and moisture level requirements. Every dry room is manufactured to meet a specific set of conditions. The type of room used for the production of batteries varies greatly from rooms that are used for producing pharmaceuticals. Each of these situations requires conditions that meet a specific dewpoint and ppmv, parts per million volume.

Each part of a dry room is carefully designed to meet the industrial requirements of the product being produced or tested. The parts of a room designed to meet specific environmental requirements has specially designed wall panels, floors, doors, sensors, and filters that ensure compliance with the needed conditions. In the majority of cases, the room is completely constructed of metal components using high efficiency particulate air (HEPA) filters, which block out 99.9% of contaminants.

Types of Fans and Dehumidifiers for Dry Rooms

Engineered into the design of a dry room is a desiccant or compressor dehumidifier. A compressor dehumidifier cools the air to remove moisture. A desiccant dehumidifier uses a chemical solution to remove moisture from the air. The desiccant chemical dehumidifier adsorbs moisture in the air. The efficiency of a desiccant dehumidifier makes it ideal for use in dry rooms though the compressor version is also used.

The fans of these specially designed rooms are normally of a centrifugal airfoil design and are mounted on vibration isolators to reduce noise and vibrations in the room. The purpose of the fans is to create the air flow to the dehumidifier. Also connected to the system is a condenser that can be air or water cooled with controls to monitor the various factors of a dry room.

The Purpose of Dry Rooms

The creation of special environments has become of increasing importance in the manufacture of specialized products and the production of drugs. Each year, new and more stringent requirements are being legislated regarding production conditions. This has made the development of specialty rooms of critical importance.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services