Testing chambers are a significant investment that require regular monitoring to ensure proper performance. It is very likely when purchasing a testing chamber that it came with a maintenance and protection agreement. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Hastest Solutions designs, manufactures and provides solutions for all environmental testing needs. For the full range of environmental test chambers, including HAST, temp/humidity, salt fog, solar radiation, high temp ovens, autoclave, and more.

Since 1959, Associated Environmental Systems (AES) has designed, manufactured, and serviced standard and custom environmental test chambers, as well as patented and patent-pending battery testing solutions. Built in the USA for precision and reliability, AES helps the world’s leading innovators test, validate, and deliver products that perform in the real world.

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Test Chamber Repair Manufacturers

In such cases, a technician will make scheduled visits to check all of the various functions of the device. There are specific systems on a chamber that need to be assessed for malfunctions and wear. This is especially true if the unit is required to produce exceptionally low temperatures.

The National Institute for Standards and Technology, NIST, a branch of the United States Department of Commerce, has a set of requirements for equipment designed to test, measure, or quantify data in laboratories and testing facilities. Testing chamber manufacturers train their technicians to abide by the regulations stipulated by the NIST, which guarantees that the service you receive will meet the highest standards.

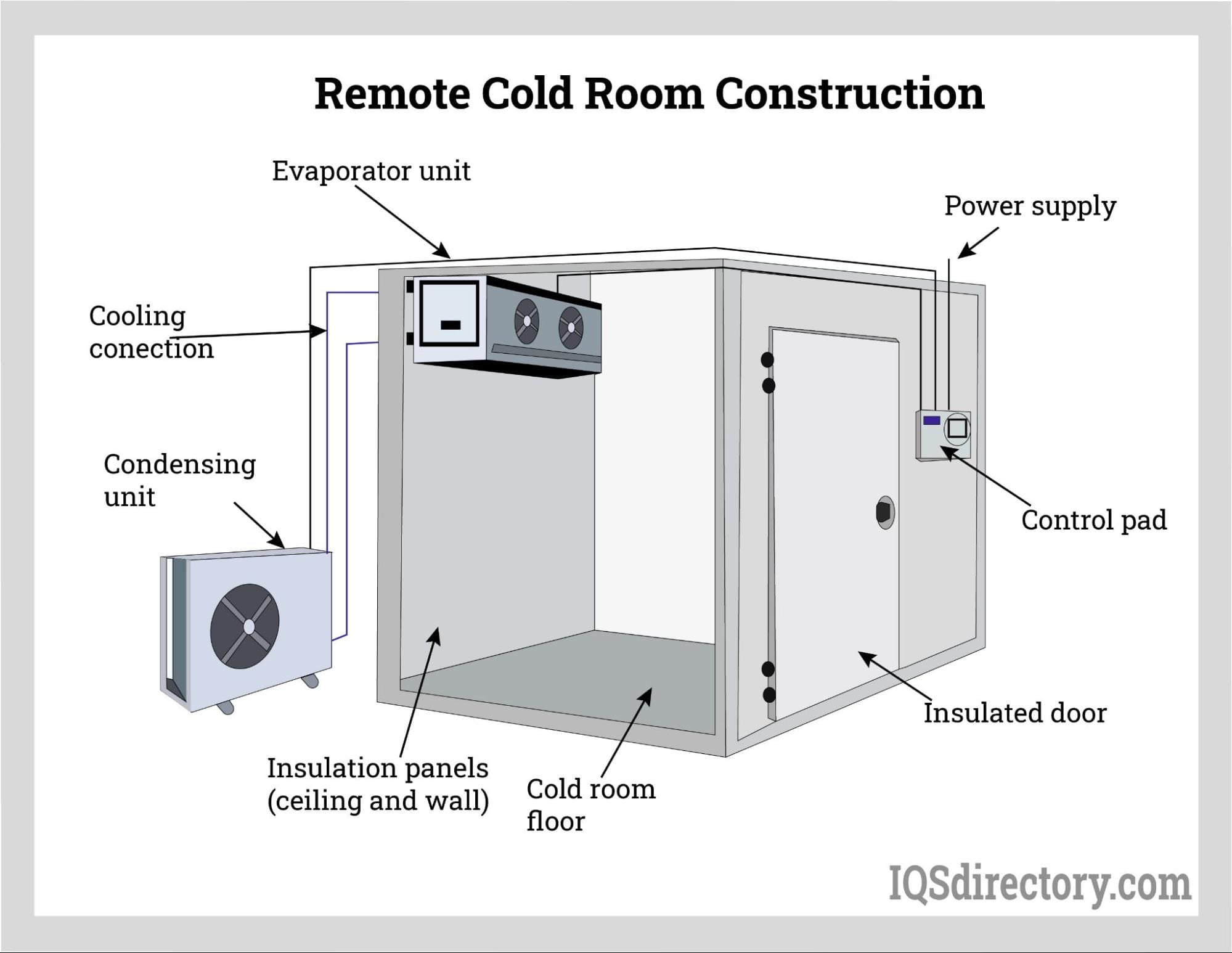

A major factor in the repair of a testing chamber is its cooling system that uses a refrigeration process to produce extremely low temperatures. The system requires uninterrupted airflow over the cooling coils to perform properly and will need to be checked using gages designed for that purpose. Since it is a refrigeration system, maintenance requires monthly visits from a technician.

The issue of airflow is also a concern for adjusting and regulating the temperature in the chamber. Repairs begin with a calibration to see how well the unit performs at various temperatures. The technician in this case uses various computer programs that give a read out of the chamber’s performance and provides necessary adjustment data.

Though on-site maintenance is common, there are incidents when the chamber may have to be returned to the manufacture for a complete overhaul. This normally happens when the equipment has had constant use over an extended period of time. In shop repairs take the form of upgrading, refurbishing, and replacing or repairing of worn parts as well as a thorough examination of technical functions to bring them up to the latest standards.

Certain in house practices can serve as preventative maintenance such as reading the test chamber instructions and training the staff who regularly use the device. A daily examination of the performance of critical functions can alert users for the need to make adjustments or call for a technician.

To get the most from a testing chamber, it is important to have it evaluated for upgrading or repair. Manufacturers have processes in place to keep a testing chamber running at peak performance.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services