Cryogenic processing is widely used by industries including automotive, aerospace, medical, and food processing due to the critical nature of their products. It can be seen in applications such as chilling and flash-freezing food for extended preservation, rocket fuel production from liquid gasses, the preparation and preservation of medicines, and in metal processing – for example, knife production, as it has been shown that metals show more resistant to wear and tear after cryogenic exposure. Read More...

Leading Cryogenic Chamber Manufacturers

Russells Technical Products has been designing and manufacturing cryogenic chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

Cincinnati Sub-Zero designs, manufactures and services custom & standard test chambers that exceed customer`s expectations. Our knowledgeable technicians are responsive to customers needs by providing after sales support as well as training on your test chambers start-up, operation & maintenance from your location or from our test chamber manufacturing facility in Ohio.

More Cryogenic Chamber Manufacturers

As with other environmental test chambers, cryogenic chambers are used by manufacturers to test their products for potential flaws and malfunctions in order to improve the design and production process. Improving a product based on environmental test results will ensure a better quality product reaches the general market and will result in fewer costs for the manufacturer in terms of replacement and reimbursement.

Cryogenic temperatures are those below -300°F and in cryogenic chambers, liquefied gasses such as liquid nitrogen will boil -320°F. While some test chambers combine environmental conditions for purposes of more thorough testing, cryogenic chambers are designed for extremely low-temperature replication.

The process of cryogenic chamber use is very time-consuming. The products and materials exposed to such extreme temperatures risk experiencing thermal shock, especially during the change of temperature – therefore the cryogenic chamber must reach its minimum temperature at a slow rate, and then return to room temperature at an equally slow rate. The test results will be most accurate if the process of moving between temperatures can be dramatically slowed down.

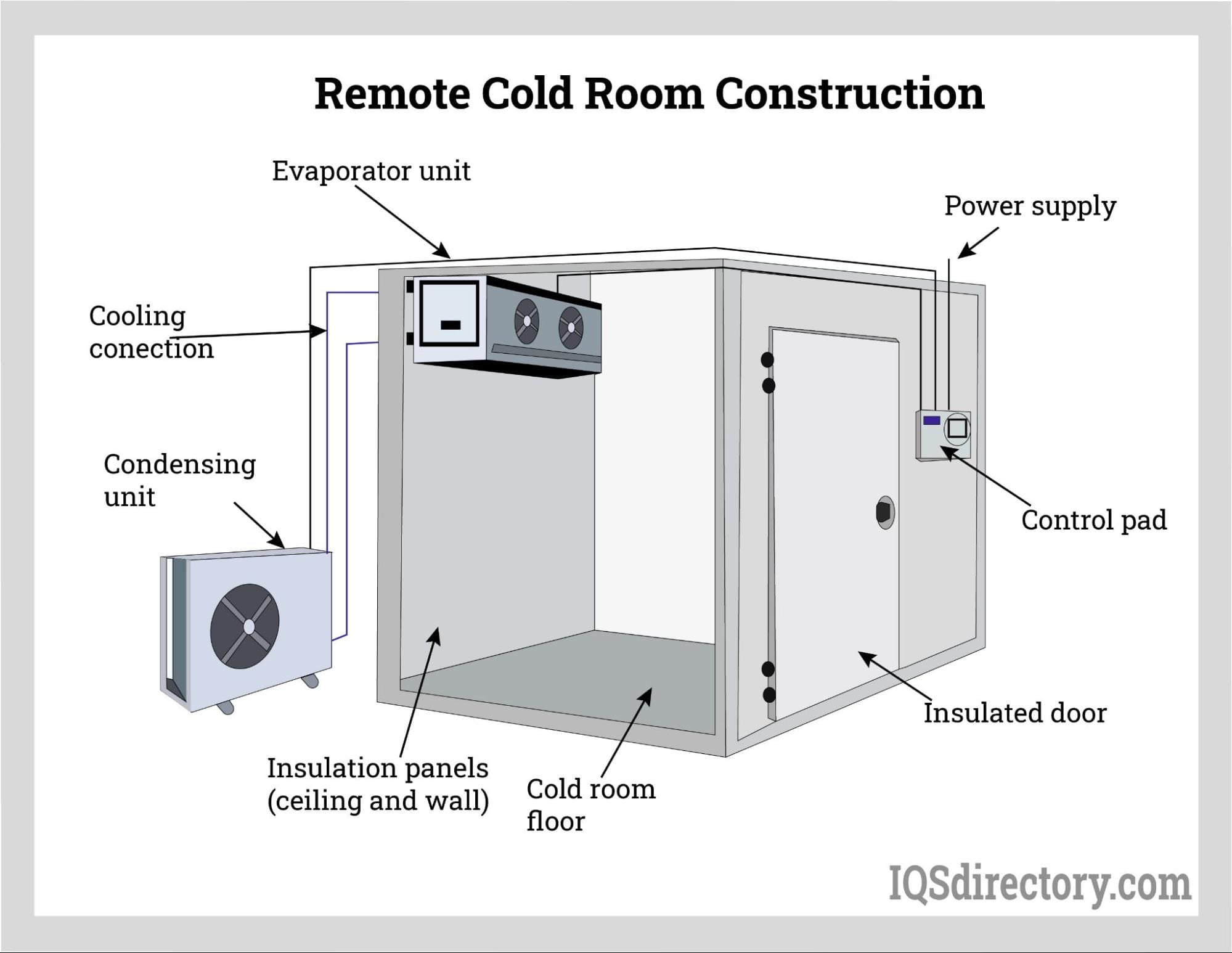

Design and construction of cryogenic chambers must also be carefully considered. Due to the extreme temperature, chamber size is an important factor in design layout as wasted space would be an unnecessary waste of energy and could adversely affect test results. The seal on a cryogenic chamber needs to be in prime condition to ensure that the temperature of the outer environment does not affect the low temperature inside the chamber.

Each element of the test and testing conditions has to be taken into consideration – such as existing environment and climate, the potential addition of interior chamber lighting and thus extra heat, and the variations that already exist between products and materials. It is time-consuming and costly, and yet cryogenic chambers are an important processing part of many industries.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services