An environmental chamber is an enclosure used to test the effects of a variety of conditions on a product, component, part, or assembly. These highly technical pieces of equipment are capable of simulating the types of conditions a product may face while in use. Read More…

Russells Technical Products has been designing and manufacturing environmental test chambers since 1972. With over 150 years of combined management experience, our company provides its customers with quality environmental test systems and advanced manufacturing techniques. Russells offers a variety of standard and custom designed chambers to meet your exact specifications.

We are leading environmental test chamber brand with over 78 years of experience designing environmental testing solutions. Over the years we have developed products for ease-of-use, reliability and performance designed to meet our customer’s testing needs and improve the safety and reliability of their products. We have a legacy of providing high quality solutions for temperature, humidity,...

A pioneer since 1962, Thermotron has been building the most recognizable environmental test equipment in the industry. Every chamber and shaker sold is handcrafted in West Michigan and comes with an intuitive controller. From automotive and defense, to electronics and medical industries, Thermotron has helped companies small and large create more reliable products. When you need to know whether...

As a leader in the test chamber industry we believe our systems are ideal for your company. We manufacture models that come standard with many useful features for testing applications. We believe that our advanced technologies are essential to the reliability of our products and our quality customer service is perfect for your needs. Feel free to visit our website or give us a call to learn more!

Hastest Solutions designs, manufactures and provides solutions for all environmental testing needs. For the full range of environmental test chambers, including HAST, temp/humidity, salt fog, solar radiation, high temp ovens, autoclave, and more.

Since 1959, Associated Environmental Systems (AES) has designed, manufactured, and serviced standard and custom environmental test chambers, as well as patented and patent-pending battery testing solutions. Built in the USA for precision and reliability, AES helps the world’s leading innovators test, validate, and deliver products that perform in the real world.

Isotech specializes in state-of-the-art environmental test chambers. With our standard and custom test chambers we strive to offer our clients products that are specifically designed to fit their needs. Isotech offers technical specifications like copper screen enclosures, RF signals, and USC-26 and USC-44 series panels.

More Environmental Test Chamber Manufacturers

Environmental Chambers

- What is an Environmental Chamber?

- Different Types of Environmental Chambers

- Uses for an Environmental Chamber

- Industries that Use Environmental Chambers

- The Types of Testing Completed in an Environmental Chamber

- And much more…

Chapter One – What is an Environmental Chamber?

An environmental chamber, also known as an environmental test chamber, climate chamber, or environmental simulation chamber, is a sophisticated, controlled enclosure engineered to replicate a wide range of environmental conditions. Environmental chambers are designed to test and evaluate products, materials, electronic components, or full assemblies by subjecting them to precisely controlled temperature, humidity, pressure, vibration, light, and other physical variables. By creating extreme or fluctuating environmental conditions, these test chambers allow manufacturers and engineers to analyze how their products perform, degrade, or fail under real-world or accelerated stress scenarios.

Through advanced programmable controls and integrated monitoring systems, environmental chambers deliver precise, repeatable, and automated testing cycles. This enables rigorous product reliability testing, compliance testing, and quality assurance for a vast array of industries—including automotive, aerospace, electronics, medical devices, pharmaceuticals, and consumer goods. Typical uses include simulating temperature extremes, rapid cycling, humidity fluctuations, corrosive atmospheres, and even high-altitude or vacuum conditions. The resulting performance data is essential for identifying potential failure points, ensuring product durability, and verifying that products meet or exceed industry standards, regulatory requirements, and customer expectations.

Utilizing environmental chambers during product design, research and development (R&D), and pre-production stages gives manufacturers a competitive edge. These chambers support faster innovation cycles, lower warranty and recall costs, and improved customer satisfaction by ensuring that only robust, reliable products reach the market. Furthermore, environmental chamber testing is often required for product certification, risk mitigation, and compliance with global standards and regulations.

Are you searching for the best climate chamber or environmental test chamber for your application? Explore our comprehensive guide below or contact leading environmental chamber manufacturers for expert recommendations tailored to your industry and testing requirements.

Chapter Two – Different Types of Environmental Chambers

Environmental chambers come in a diverse array of sizes, designs, and test capabilities to suit the evolving and specialized needs of today’s industries. Whether you require accelerated life testing, temperature and humidity cycling, corrosion resistance analysis, or complex, multi-stressor simulation, there is a test chamber solution optimized for your unique use case. Environmental chambers may be configured for single-mode or multi-mode testing, with advanced programmable controls allowing for sequential or simultaneous application of various test parameters.

When selecting an environmental test chamber, it’s important to consider the key parameters to be simulated—such as temperature, humidity, vibration, altitude, pressure, light, and corrosive atmospheres. Many manufacturers offer modular or custom-designed chambers for specialized testing, and there are also standardized models for common industry protocols. Below, we outline the most widely used types of environmental chambers and their core features.

Types of Environmental Chambers

Temperature Chambers

Temperature test chambers, also known as thermostatic or thermal cycling chambers, are designed to replicate extreme and rapidly changing temperatures. These chambers can accurately cycle between subzero temperatures (as low as –94°F/–70°C) to high heat (up to 356°F/180°C or more). Temperature chambers are essential for thermal shock testing, burn-in testing, accelerated aging studies, and operational stability assessments. They are used extensively in the electronics, automotive, aerospace, defense, and materials industries to ensure products will operate safely and reliably across a wide range of environmental conditions. Are you comparing temperature test chambers? Evaluate features such as temperature range, ramp rate, uniformity, and data logging capabilities.

Looking for the right temperature test chamber for your product? Consider your required temperature range, chamber volume, and control accuracy before requesting a quote.

Humidity Chambers

Humidity test chambers (also known as climatic chambers) allow for precise simulation of moisture-laden environments, which are vital for evaluating corrosion resistance, material stability, and product shelf life. These chambers control both temperature and relative humidity, enabling static or dynamic climatic cycling. Common applications include testing of electronics, pharmaceuticals, food packaging, and building materials, where humidity can accelerate degradation or failure.

For combined stress testing, temperature-humidity chambers integrate both environmental factors, supporting comprehensive reliability and accelerated aging analysis.

Vibration Chambers

Vibration test chambers (also called mechanical shock or electrodynamic chambers) subject products to controlled vibration and shock profiles. These chambers simulate the forces experienced during transportation, operation, or seismic activity, and are often combined with temperature and humidity conditions for multi-axis, multi-stressor testing. Vibration testing is a central element of Highly Accelerated Life Testing (HALT) and Highly Accelerated Stress Screening (HASS), helping to identify latent weaknesses and verify robust product designs.

Applications range from automotive and aerospace components to consumer electronics and industrial machinery.

Stability Chambers

Stability test chambers are engineered to maintain long-term, tightly controlled temperature, humidity, and light conditions—enabling critical stability studies. These chambers are essential for determining the shelf life and degradation rates of pharmaceuticals, biotech products, foods, cosmetics, and packaging materials. Adherence to ICH, FDA, and WHO guidelines is ensured, making these chambers indispensable for regulatory compliance and product safety.

Looking to comply with ICH or FDA stability testing protocols? Choose a stability chamber with validated uniformity, data logging, and alarm systems.

Salt Spray Chambers

Salt spray (fog) chambers create aggressive saline atmospheres to accelerate corrosion and evaluate the effectiveness of protective coatings, metals, and surface finishes. These chambers are maintained at controlled temperatures (often 95°F/35°C) and salt concentrations as per ASTM B117, ISO, or other global corrosion test standards. Salt spray testing is widely utilized in the automotive, marine, construction, and industrial sectors for predicting the long-term durability and corrosion resistance of materials and assemblies.

Do you need to test for corrosion resistance? Compare salt spray chamber options with programmable cycle duration, maintenance features, and compliance certifications.

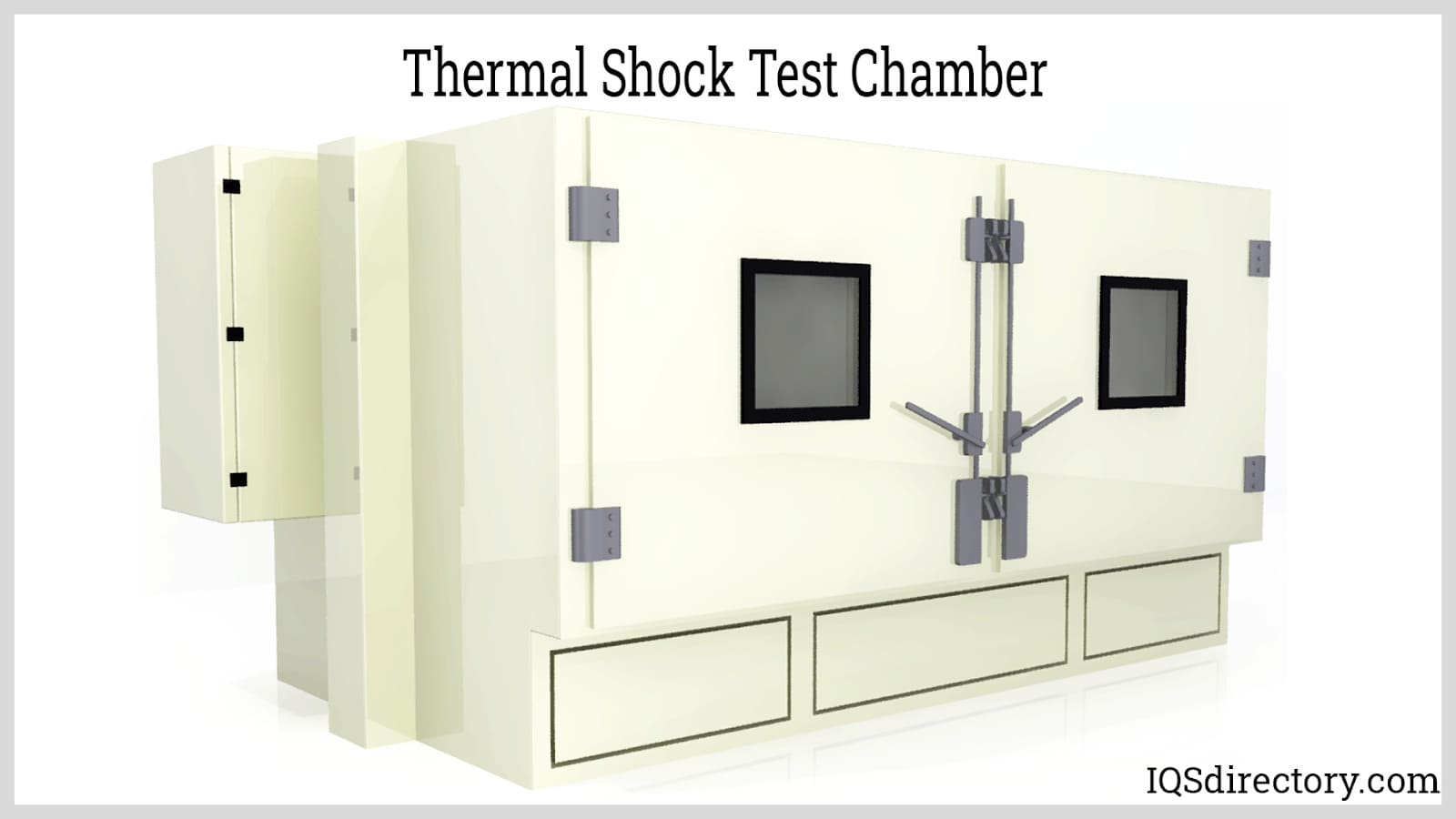

Thermal Shock Chambers

Thermal shock test chambers provide rapid and extreme temperature transitions, often using separate hot and cold zones to cycle samples between environments with temperature differentials exceeding 54°F (30°C) per minute. These tests are critical for uncovering failures in solder joints, adhesives, composites, and multi-material assemblies, especially in high-reliability sectors like automotive, aerospace, and electronics.

Thermal shock testing can reveal issues with material expansion/contraction and structural integrity that may not appear under gradual temperature cycling.

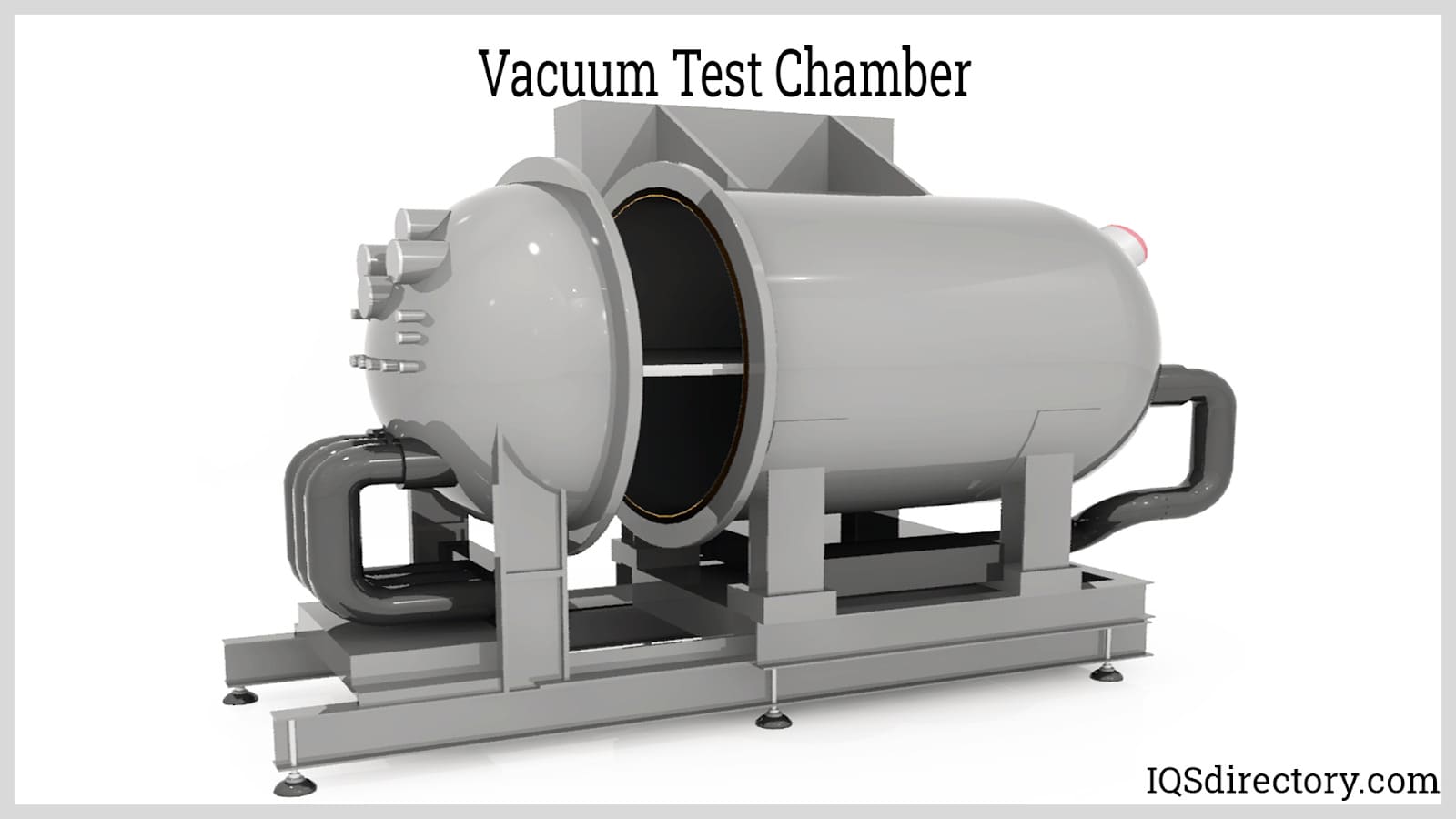

Vacuum Chambers

Vacuum test chambers simulate low-pressure or near-vacuum conditions by removing air and gases from the enclosure. This is essential for testing aerospace, satellite, and space exploration equipment, as well as for outgassing analysis and leak detection. Vacuum chambers are also used for high-altitude simulation and research into chemical and physical processes under reduced pressure.

Are you preparing for high-altitude or space-related product testing? Consult with vacuum chamber manufacturers about pressure range, leak detection, and test customization options.

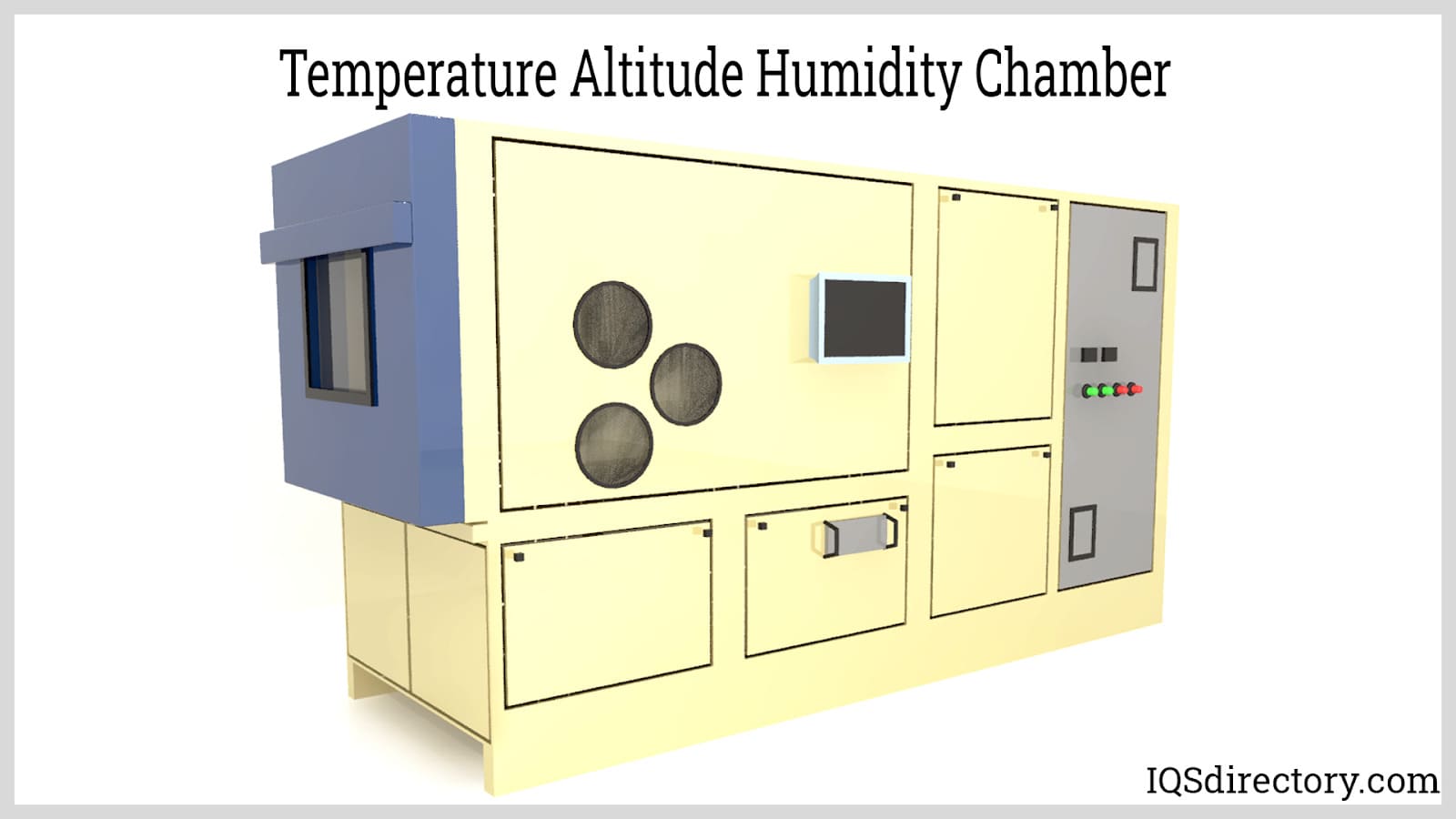

Altitude Chambers

Altitude test chambers replicate low-pressure, high-altitude environments—up to 30,000 meters—allowing for decompression, explosive decompression, and pressure cycling tests. These chambers are widely used for qualifying aerospace, automotive, and defense equipment for safe operation at different elevations.

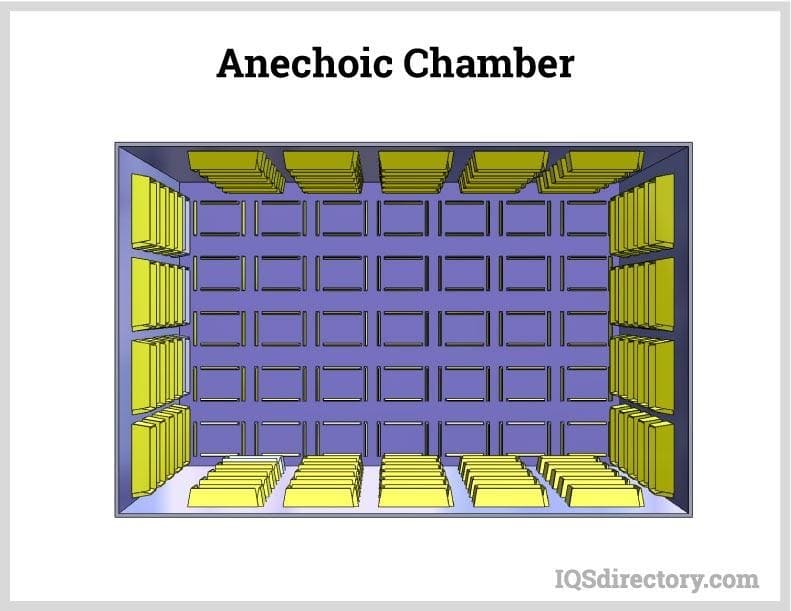

Anechoic Chambers

An anechoic chamber is a special test environment used for electromagnetic compatibility (EMC) and acoustic testing. It features sound-absorbing and RF-absorbing materials to eliminate sound and electromagnetic wave reflections, ensuring a noise- and interference-free setting for sensitive measurements. Anechoic chambers are commonly used for EMC compliance, noise testing in automotive and electronics, and acoustic research.

Do you need an EMC or acoustic test solution? Review anechoic chamber specifications for frequency range, internal dimensions, and absorption characteristics.

Chapter Three – Uses for Environmental Chambers

Before the advent of modern environmental test chambers, manufacturers depended on lengthy field tests and real-world user feedback to assess product reliability. This reactive approach often resulted in costly delays, warranty claims, and unforeseen failures. Today, environmental chambers empower companies to proactively simulate years of service in a matter of days or weeks, under precisely controlled and repeatable conditions.

Environmental test chambers now play a critical role in product development, regulatory certification, accelerated aging studies, and ongoing quality assurance. They enable manufacturers to validate performance, enhance safety, and gain data-driven insight into product durability—thereby reducing time-to-market and minimizing costly recalls.

Common Uses for Environmental Test Chambers

Environmental chambers are used to simulate and study the effects of environmental stressors on a wide range of products and materials. Typical uses include:

Temperature Variations or Thermal Testing

Assessing a product’s ability to withstand extreme temperatures, rapid temperature changes, and thermal cycling. This is especially important for electronics, automotive parts, aerospace components, and industrial equipment where thermal stress can lead to failure or reduced lifespan.

Humidity Testing

Evaluating how moisture and humidity—alone or in combination with temperature—affect product performance, corrosion rates, condensation, and material stability. This is vital for the electronics, medical, pharmaceutical, and packaging industries.

Air Pressure and Altitude Testing

Simulating low-pressure or high-altitude conditions for aerospace, automotive, and defense applications. This testing uncovers issues such as leakage, material expansion, and functional performance at different elevations or in vacuum environments.

Thermal Shock Testing

Rapidly cycling products between hot and cold zones to identify structural weaknesses or failures in solder joints, adhesives, and multi-material assemblies.

Accelerated Aging and Life Testing

Subjecting products to heightened stress conditions to simulate years of exposure in a short timeframe. This is especially important for predicting shelf life, reliability, and long-term performance of consumer goods, medical devices, and packaging materials.

Xenon-Arc and UV Exposure Testing

Using intense artificial sunlight or ultraviolet light to simulate solar radiation, revealing degradation, fading, or material breakdown due to long-term outdoor exposure. This is critical for building materials, automotive parts, paints, and coatings.

Salt Spray or Corrosion Testing

Exposing samples to a saline fog to accelerate corrosion and evaluate the effectiveness of protective coatings, metals, and surface finishes. This is essential for automotive, marine, construction, and infrastructure applications.

Are you seeking to optimize your corrosion resistance? Compare salt spray test chambers certified to ASTM B117 and ISO standards.

Vibration and Mechanical Shock Testing

Evaluating products for resistance to vibration, repetitive shocks, and mechanical stresses encountered during transport or in operational environments.

Altitude Testing

Assessing product performance and safety under simulated high-altitude, low-pressure environments, often combined with temperature and humidity cycling for a comprehensive analysis.

Curious how environmental testing impacts your industry? Contact an expert in environmental test chambers about customized test protocols for your specific product or application.

Chapter Four – Industries That Use Environmental Chambers

Environmental test chambers are indispensable across a wide spectrum of industries, supporting innovation, product validation, compliance certification, and failure analysis. By delivering precise and repeatable environmental simulation, these chambers help manufacturers and researchers accelerate time-to-market, reduce risk, and control warranty costs.

Products in nearly every sector—commercial, industrial, consumer, or defense—are subject to environmental stressors such as temperature, humidity, vibration, and pressure. Environmental chamber testing is essential for optimizing performance, extending product lifespan, and certifying compliance with standards and regulations.

Key Industrial Applications of Environmental Test Chambers

Automotive

The automotive industry leverages environmental chambers for testing everything from small electronic components to full vehicle assemblies. Chambers enable assessments of thermal, humidity, vibration, salt spray, and weathering resistance, ensuring vehicles meet stringent global performance, safety, and emissions standards. Environmental chamber testing is fundamental for enhancing vehicle reliability, durability, and quality assurance in a competitive marketplace.

Electronics

Electronics manufacturers utilize environmental test chambers to assess reliability and performance of integrated circuits, semiconductors, printed circuit boards (PCBs), sensors, and assemblies. Chambers simulate temperature, humidity, vibration, and combined stress cycles to identify latent defects and ensure compliance with standards such as IPC, IEEE, and JEDEC.

Pharmaceutical and Biotechnology

Stability and environmental test chambers are integral in the pharmaceutical and biotech industries for shelf-life testing, packaging evaluation, and regulatory compliance with FDA, ICH, and WHO guidelines. These chambers ensure drugs, vaccines, and biopharmaceutical products maintain efficacy and safety throughout the distribution and storage lifecycle.

Defense and Military

The defense sector relies on environmental test chambers to validate equipment against rigorous MIL-STD requirements. Chambers simulate extreme temperatures, humidity, vibration, altitude, and combined stressors to guarantee mission-critical reliability and personnel safety in the harshest environments.

Medical Devices

Environmental chambers play a crucial role in the medical device industry, supporting FDA and international regulatory compliance for sterility, performance, and long-term reliability. Test chambers help validate medical equipment, surgical tools, and diagnostic devices, particularly those intended for life-critical or sterile environments.

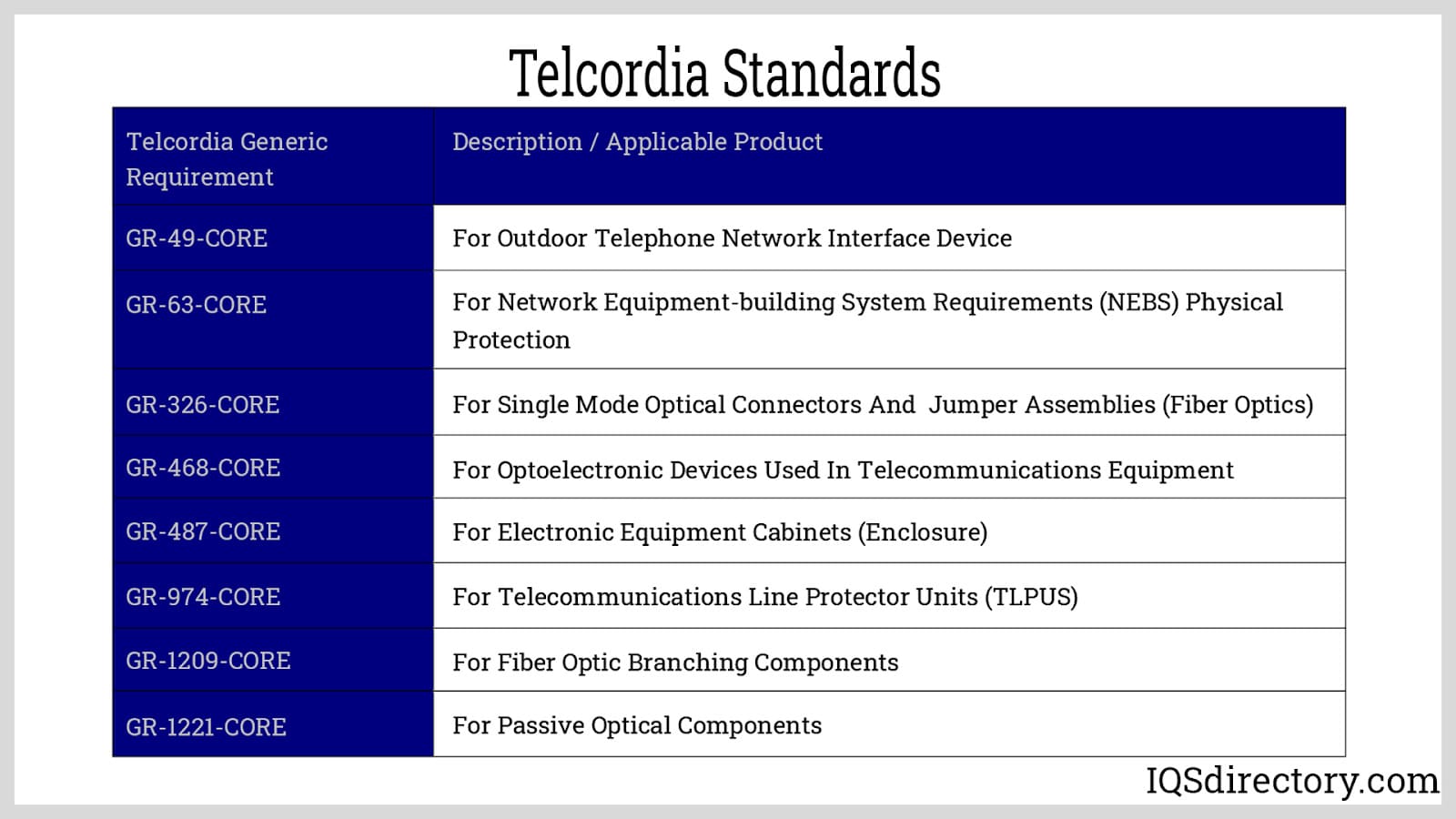

Telecommunications

Telecommunications manufacturers use environmental test chambers to meet Telcordia, TIA, and IEC standards, simulating temperature, humidity, altitude, and vibration stresses. Reliable environmental testing ensures consistent performance of infrastructure, networking hardware, and mobile devices.

Solar and Renewable Energy

Environmental testing in the solar and renewable energy sector focuses on validating the durability of solar panels, photovoltaic modules, inverters, and related electronics. Chambers perform thermal cycling, humidity freeze, UV exposure, and hail impact testing in accordance with IEC, UL, and ASTM standards.

Aerospace and Aviation

Aerospace and aviation industries require environmental test chambers to replicate high-altitude, vacuum, vibration, and temperature extremes. Compliance with SAE, FAA, and NASA standards ensures safety, operational reliability, and performance of critical flight systems, avionics, and structural components.

Other important sectors utilizing environmental test chambers include food and beverage, cosmetics, construction, marine, rail, industrial machinery, and consumer electronics. Not sure which chamber suits your industry? Connect with a specialized manufacturer for tailored advice.

Chapter Five – Types of Environmental Chambers

Environmental test chambers are available in an extensive range of sizes and configurations—from compact benchtop models for laboratory research to massive walk-in and drive-in chambers for full-scale vehicle or equipment testing. The right choice depends on your product size, test requirements, throughput needs, and regulatory standards to be met.

Types of Environmental Chambers by Size and Configuration

Benchtop Environmental Chambers

Benchtop environmental chambers are compact, space-efficient units ideal for R&D labs, universities, and small-scale production environments. Despite their small footprint, benchtop chambers offer precise temperature, humidity, and sometimes vibration control, along with programmable logic for repeatable test cycles. They are particularly suited for testing small electronic components, materials, medical devices, and research samples.

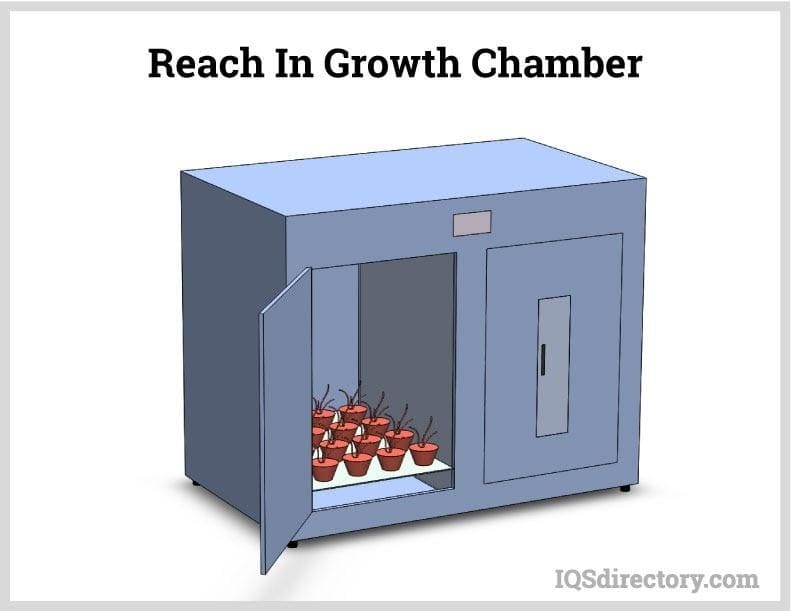

Reach-In Environmental Chambers

Reach-in chambers are vertically oriented, mobile, and typically floor-mounted, offering flexibility for a wide array of testing protocols. They often feature observation windows, user-friendly controls, and are suitable for temperature, humidity, and combined stress testing of medium-sized components, sub-assemblies, and prototypes.

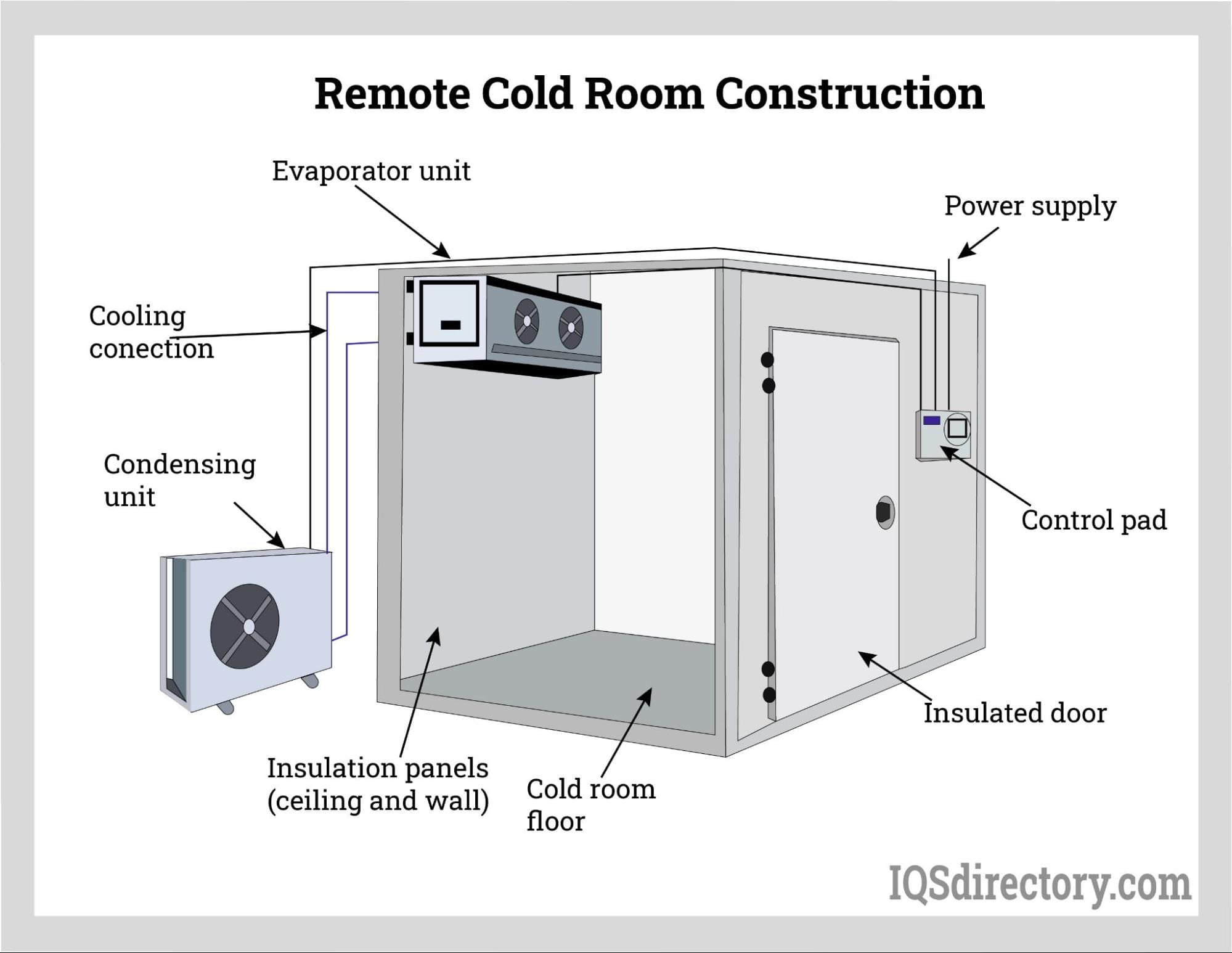

Walk-In Environmental Chambers

Walk-in test chambers offer large, customizable environments for testing bigger products, assemblies, or bulk materials. Walk-in chambers are available in modular or welded construction and can be configured to replicate a wide spectrum of environmental conditions—supporting multi-variable and long-duration testing with advanced data logging and regulatory traceability.

Key features include reinforced flooring, access ports, sound insulation, and integrated safety systems.

Drive-In Environmental Chambers

Drive-in chambers are engineered for full-vehicle, aircraft, or heavy equipment testing. These large-scale, custom-built chambers are capable of reproducing a broad range of environmental stressors—including extreme temperatures, humidity, salt spray, vibration, and altitude—providing comprehensive durability and performance assessment for automotive, aerospace, and industrial machinery manufacturers.

Highly Accelerated Life Test (HALT) Chambers

HALT chambers are designed to push products to their operational and destructive thresholds using extreme thermal cycling, rapid temperature transitions, vibration, and combined stressors. This rapid testing uncovers design weaknesses and supports robust product improvement prior to production release.

Highly Accelerated Stress Screening (HASS) Chambers

HASS chambers are employed after HALT, applying stringent, repetitive stress cycles to screen out latent defects in production units, ensuring consistent quality and reliability—especially in mission-critical industries such as aerospace, defense, and advanced electronics manufacturing.

Environmental Chamber Construction and Features

Most environmental chambers, regardless of size, feature certain key design elements for optimal performance and safety:

- Door – Airtight, gasket-sealed doors (often using flexible plastics or rubber) to prevent environmental leakage and contamination.

- Insulation – Thick insulation in doors and walls to ensure strict temperature and humidity control, minimizing external influence for accurate results.

- Walls – Durable steel exteriors and corrosion-resistant stainless steel interiors to maintain structural integrity and cleanliness.

- Windows – Double-paned, transparent polymer observation windows for safe monitoring during active tests.

- Controllers and Monitors – Advanced, often touchscreen, controllers and monitoring systems with remote access, USB/Ethernet connectivity, programmable test sequencing, real-time data collection, and compliance documentation.

When evaluating environmental chambers, consider factors such as chamber volume, performance specifications (temperature/humidity/vibration range and uniformity), data acquisition capabilities, energy efficiency, and regulatory compliance features. Looking to upgrade or expand your testing capability? Request quotes from multiple manufacturers and compare warranty, service, and customization options.

Chapter Six – Environmental Chamber Regulations

Environmental chambers are subject to a comprehensive framework of industry-specific standards, regulatory requirements, and safety protocols. Compliance is particularly critical in sectors such as medical devices, pharmaceuticals, aerospace, defense, and automotive, where product failure can have serious consequences for safety, health, or mission success.

Key regulatory bodies and standards include:

- FDA, WHO, ICH, and CDC for pharmaceutical and biotechnology product testing—governing sterility, stability, and packaging validation.

- FDA, ASTM, and IEC for medical device environmental testing—ensuring patient safety and product reliability.

- MIL-STD protocols for military and defense equipment—defining rigorous environmental, mechanical, and operational testing procedures.

- ASTM, SAE, UL, and DOT for automotive and transportation—establishing comprehensive test methods for durability and compliance.

- IEEE, JEDEC, and IPC for electronics—covering accelerated life, humidity, and vibration testing.

- Telcordia, TIA, and EIA for telecommunications—ensuring network reliability under environmental stress.

- ANSI and IEC for cross-industry guidance, safety, and interoperability.

Adherence to these standards is essential for market access, risk mitigation, consumer protection, and legal compliance. Environmental chamber manufacturers and users must stay current with evolving global standards, best practices, and documentation requirements to ensure valid, effective, and legally defensible test outcomes.

Do you need guidance on regulatory compliance for environmental testing? Consult with experienced chamber manufacturers or industry testing consultants for up-to-date advice and support.

Conclusion

- An environmental chamber is a specialized enclosure for simulating a wide range of environmental conditions—enabling comprehensive testing, validation, and certification of products, components, and materials.

- Sophisticated test protocols expose products to realistic or accelerated stress, yielding critical data on performance, reliability, and regulatory compliance.

- Environmental chambers are available in diverse sizes and configurations, from benchtop research units to drive-in vehicle testing systems, supporting industries ranging from aerospace and defense to pharmaceuticals and consumer electronics.

- Technological advances in environmental chambers empower manufacturers to enhance product quality, reduce failures, streamline compliance, and accelerate innovation.

- Strict adherence to industry regulations and international standards is vital for effective, reliable, and market-approved environmental testing.

Ready to advance your product testing strategy? Explore our directory of leading environmental chamber manufacturers, or request a consultation to identify the ideal test chamber solution for your needs.

Still have questions about environmental test chambers, compliance, or applications? Use our search or contact form to connect with an expert and get detailed answers for your specific project.

Check out our Linear Actuators website

Check out our Clean Rooms website

What is an environmental chamber?

An environmental chamber is a controlled enclosure designed to replicate a wide range of physical conditions, such as temperature, humidity, pressure, vibration, and light. These chambers are used to test and evaluate the durability, reliability, and performance of products, electronic components, materials, or assemblies under real-world or accelerated stress scenarios.

What are the different types of environmental chambers?

Different types of environmental chambers include temperature chambers, humidity chambers, vibration chambers, stability chambers, salt spray chambers, thermal shock chambers, vacuum chambers, altitude chambers, and anechoic chambers. Each type is engineered to simulate specific environmental stressors for targeted product testing and reliability assessments.

How are environmental chambers used in product testing?

Environmental chambers are used to proactively simulate years of service for products in a matter of days or weeks through tightly controlled tests. Typical uses include thermal testing, humidity and air pressure simulations, thermal shock, accelerated aging, UV exposure, corrosion testing, vibration, and altitude assessments, ensuring that products meet safety, reliability, and regulatory requirements.

Which industries commonly use environmental test chambers?

Industries that commonly use environmental test chambers include automotive, electronics, pharmaceutical and biotechnology, defense, medical devices, telecommunications, solar and renewable energy, aerospace, aviation, food and beverage, cosmetics, marine, construction, and consumer goods. These industries rely on chambers for product validation, compliance, and reliability testing.

What configurations and sizes do environmental chambers come in?

Environmental chambers are available as compact benchtop units for laboratory testing, reach-in and walk-in chambers for medium to large samples, and drive-in chambers for full-vehicle or heavy equipment testing. Specialized chambers include Highly Accelerated Life Test (HALT) and Highly Accelerated Stress Screening (HASS) units for extreme stress applications.

What regulations and standards govern environmental chambers and testing?

Environmental chambers are subject to industry-specific standards and regulatory requirements, including FDA, WHO, ICH, ASTM, IEC, MIL-STD, SAE, UL, IEEE, JEDEC, IPC, Telcordia, TIA, EIA, ANSI, and DOT. Compliance ensures product safety, efficacy, market access, and reliability across critical sectors such as medical devices, pharmaceuticals, aerospace, defense, and automotive.

What should be considered when choosing an environmental chamber?

When choosing an environmental chamber, consider test requirements such as temperature and humidity range, chamber size, control accuracy, monitoring and data logging capabilities, energy efficiency, regulatory compliance, and options for customization or modular expansion. It is essential to match the chamber’s capabilities to your product’s testing needs and applicable industry standards.

Calibration Services

Calibration Services Clean Rooms

Clean Rooms Data Acquisition Systems

Data Acquisition Systems Dynamometers

Dynamometers Environmental Test Chamber

Environmental Test Chamber Leak Detectors

Leak Detectors Load Cells

Load Cells Machine Vision Systems

Machine Vision Systems Scales

Scales Thermocouples

Thermocouples Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services